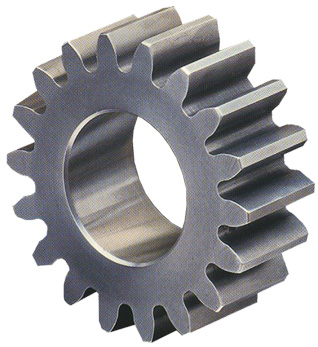

SPUR GEAR

Spur gears or straight-cut gears are the simplest type of gear. They consist of a cylinder or disk with the teeth projecting radially, and although they are not straight-sided in form (they are usually of special form to achieve constant drive ratio, mainly involute), the edge of each tooth is straight and aligned parallel to the axis of rotation. These gears can be meshed together correctly only if they are fitted to parallel shafts.

Spur gears are the most commonly used gear type. They are characterized by teeth which are perpendicular to the face of the gear. Spur gears are by far the most commonly available, and are generally the least expensive. The basic descriptive geometry for a spur gear is shown in the figure below.

Spur gears, the most common type of gear, are often used because they are the simplest to design and manufacture, and are the most efficient, as well. Spur gears have straight teeth that are situated parallel to the gear axis. They are most commonly used in power tools and robotics applications. Although they are common and efficient, spur gears have disadvantages as well.

Advantages of Spur Gear:

- Spur gears have high power transmission efficiency.

- They are compact and easy to install.

- They offer constant velocity ratio.

- Unlike belt drives, spur gear drives have no slip.

- Spur gears are highly reliable.

- They can be used to transmit large amount of power (of the order of 50,000 kW).

Disadvantages of Spur Gear:

- Spur gear drives are costly when compared to belt drives.

- They have a limited center distance. This is because in a spur gear drive, the gears should be meshed and they should be in direct contact with each other.

- Spur gears produce a lot of noise when operating at high speeds.

- They cannot be used for long distance power transmission.

- Gear teeth experience a large amount of stress.

- Spur gears generally cannot be used when a direction change between the two shafts is required.

Applications of Spur Gear:

Spur gears have a wide range of applications. They are used in:

- Metal cutting machines

- Power plants

- Marine engines

- Mechanical clocks and watches

- Fuel Pumps

- Washing Machines

- Gear motors and gear pumps

- Rack and pinion mechanisms

- Material handling equipments

- Automobile gear boxes

- Steel mills

- Rolling mills

Post Comment

You must be logged in to post a comment.