All Content of the Stress – Strain

- Introduction : In engineering practice, the machine parts are subjected to various forces which may be due to either one or more of the following:

- Energy Transmitted,

- Weight of machine,

- Frictional resistance,

- Inertia of reciprocating parts,

- Change of temperature, and

- Lack of balance of moving parts.

The different forces acting on a machine parts produces various types of stresses, which will be discussed in this chapter.

- Load : It is defined as any external force acting upon a machine part. See more…

- Stress and its types : The internal force per unit area at any section of the body is known as unit stress or simply a stress. See more…

- Strain and its types : When a system of forces or loads act on a body, it undergoes some deformation. This deformation per unit length is known as unit strain or simply a strain. See more…

- Tensile Stress and strain : Click to see more about …

- Compressive stress and strain : Click to see more about …

- Young’s Modulus or Modulus of Elasticity : Hookes law…

- Shear Stress and Strain : When a body is subjected to two equal and opposite forces acting … See more

- Shear Modulus or Modulus of Rigidity : It has been found experimentally that within the elastic limit, the shear stress is directly proportional to shear strain. See more…

- Bearing Stress : A localised compressive stress at the surface…see more

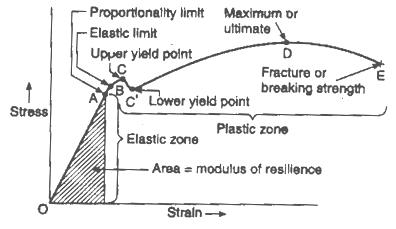

- Stress-Strain Diagram : Click here to see diagram…

- Working Stress : When designing machine parts, it is desirable to keep the stress lower then the maximum or ultimate stress at which failure of the material takes place. This stress is known as the working stress or design stress. It is also known as safe or allowable stress.

Note : By failure it is not meant actual breaking of the material. Some machine parts are said to fail when they

have plastic deformation set in them, and they no more perform their function satisfactory. - Factor of Safety : It is defined, in general, as the ration of maximum stress to the working stress. See more…

- Selection of Factor of Safety : Click here to see…

- Stresses in Composite Bars : A composite bar may be defined as a bar… see more

- Stresses Due to Chang in Temperature – Thermal Stresses : Click here to see…

- Linear and Lateral Strain : Every direct stress is accompanied by a strain in its own direction which is known as linear strain and an opposite kind of strain in every direction, at right angles to it, is known as … Click here to see more…

- Poisson’s Ratio : It has been found experimentally that when a body is stressed within elastic limit, the lateral strain bears a constant ratio to the linear strain, Mathematically… see more…

- Volumetric Strain : The ratio of the change in volume to the original volume is known as volumetric strain. See more…

- Bulk Modulus : The ration of the direct stress to the corresponding volumetric strain is known as bulk modulus. See more…

- Relation between Bulk Modulus and Young’s Modulus : Click here to see relation…

- Relation between Young’s Modulus and Modulus of Rigidity : Click here to see relation…

- Impact Stress : The stress produced in the member due to the falling load is known as impact load. see more…

- Resilience : Click here to see…

Reference

A textbook of Machine Design by R.S.Khurmi and J.K.Gupta

Post Comment

You must be logged in to post a comment.