Testing of Fatique

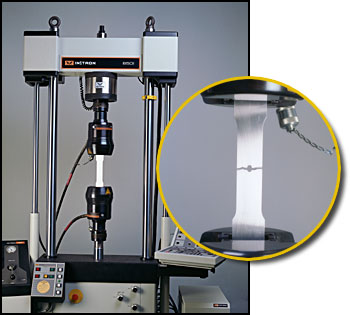

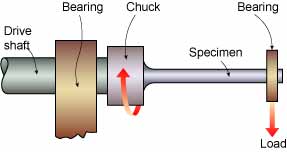

Material subjected to static and cyclic loading, yield strength is the main criterion for product design. However for dynamic loading conditions, the fatigue strength or endurance limit of a material is used in main criteria used for designing of parts subjected to repeated alternating stresses over an extended period of time. Fig shows a fatigue test set up determining the fatigue strength of material. The fatigue test determines the stresses which a sample of material of standard dimensions can safely endure for a given number of cycles. It is performed on a test specimen of standard metal having a round cross-section, loaded at two points as a rotating simple beam, and supported at its ends. The upper surface of such a standard test specimen is always in compression and the lower surface is always in tension.

The maximum stress in metal always occurs at the surface, halfway along the length of the standard test specimen, where the cross section is minimum. For every full rotation of the specimen, a point in the surface originally at the top centre goes alternately from a maximum in compression to a maximum in tension and then back to the same maximum in compression. Standard test specimens are tested to failure using different loads, and the number of cycles before failure is noted for each load. The results of such tests are recorded on graphs of applied stress against the logarithm of the number of cycles to failure. The curve is known as S-N curve. Copied from Introduction to Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.