Tungusten Inert Gas Welding

(TIG)

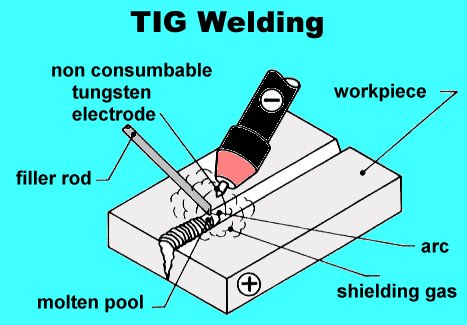

In this process a non-consumable tungsten electrode is used with an envelope of inert shielding gas around it. The shielding gas protects the tungsten electrode and the molten metal weld pool from the atmospheric contamination. The shielding gases generally used are argon, helium or their mixtures. Typical tungsten inert gas welding setup is shown in Fig.

Electrode materials

The electrode material may be tungsten, or tungsten alloy (thoriated tungsten or zirconiated tungsten). Alloy-tungsten electrodes possess higher current carrying capacity, produce a steadier arc as compared to pure tungsten electrodes and high resistance to contamination.

Electric power source

Both AC and DC power source can be used for TIG welding. DC is preferred for welding of copper, copper alloys, nickel and stainless steel whereas DC reverse polarity (DCRP) or AC

is used for welding aluminium, magnesium or their alloys. DCRP removes oxide film on magnesium and aluminium.

Inert gases

The following inert gases are generally used in TIG welding:

1. Argon

2. Helium

3. Argon-helium mixtures

4. Argon-hydrogen mixtures

Tig Nozzle

The nozzle or shield size (the diameter of the opening of the shroud around the electrode) to be chosen depends on the shape of the groove to be welded as well as the required gas flow rate. The gas flow rate depends on the position of the weld as well as its size. Too high a gas consumption would give rise to turbulence of the weld metal pool and consequently porous welds. Because of the use of shielding gases, no fluxes are required to be used in inert gas shielded arc welding. However for thicker sections, it may be desirable to protect the root side of the joint by providing a flux. The process is generally used for welding aluminium, magnesium and stainless steel. Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.

Post Comment

You must be logged in to post a comment.