Working Stresses in Belts, Density of Belt Materials :

Working Stresses in Belts

The ultimate strength of leather belt varies from 21 to 35 MPa and a factor of safety may be taken as 8 to 10. However, the wear life of a belt is more important than actual strength. It has been shown by experience that under average conditions an allowable stress of 2.8 MPa or less will give a reasonable belt life. An allowable stress of 1.75 MPa may be expected to give a belt life of about 15 years.

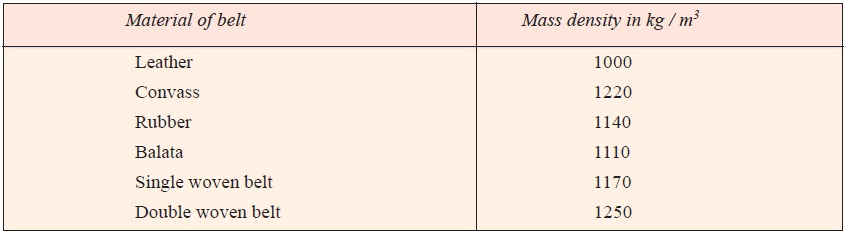

Density of Belt Materials

The density of various belt materials are given in the following table 1 :

Belt transect

Belt transects are used in biology to estimate the distribution of organisms in relation to a certain area, such as the seashore or a meadow. It records all the species found between two lines and how far they are for a certain place or area and how many of them there are. An interrupted belt transect records all the species found in quadrats (square frames) placed at certain intervals along a line.

The belt transect method is similar to the line transect method but gives information on abundance as well as presence, or absence of species. It may be considered as a widening of the line transect to form a continuous belt, or series of quadrats.

In this method, the transect line is laid out across the area to be surveyed and a quadrat is placed on the first marked point on the line. These marked points should be a set amount of space apart. The plants and/or animals inside the quadrat are then identified and their abundance estimated. Animals can be counted within the quadrat, or collected, while it is usual to estimate the percentage cover of plant species. Cover is the area of the quadrat occupied by the above-ground parts of a species when viewed from above. The canopies of the plants inside the quadrat will often overlap each other, so the total percentage cover of plants in a single quadrat will frequently add up to more than 100%.

Quadrats are sampled all the way down the transect line, at each marked point on the line, or at some other predetermined interval (or even randomly) if time is short. It is important that the same person should do the estimations of cover in each quadrat, because the estimation is likely to vary from person to person. If different people estimate percentage cover in different quadrats, then an element of personal variation is introduced which will lead to less accurate results. Sampling should always be as least destructive as possible and trampling the surrounding area should be avoided when carrying out a survey. Not only is there a risk of damaging the area, but there is also a risk of reducing the population or percentage cover of the species being surveyed.

Reference Wikipedia and A textbook of Machine Design by R.S.Khurmi and J.K.Gupta

Post Comment

You must be logged in to post a comment.