DESIGN CONSIDERATIONS IN PATTERN MAKING

The following considerations should always be kept in mind while designing a pattern.

1. All Abrupt changes in section of the pattern should be avoided as far as possible.

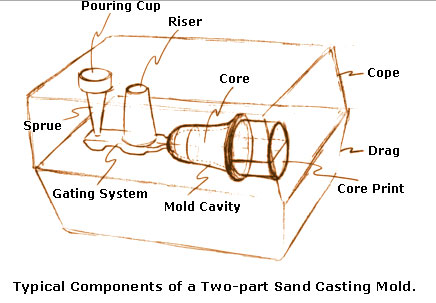

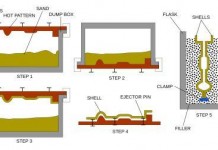

2. Parting line should be selected carefully, so as to allow as small portion of the pattern as far as possible in the cope area.

3. The thickness and section of the pattern should be kept as uniform as possible.

4. Sharp corners and edges should be supported by suitable fillets or otherwise rounded of. It will facilitate easy withdrawal of pattern, smooth flow of molten metal and ensure a sound casting.

5. Surfaces of the casting which are specifically required to be perfectly sound and clean should be so designed that they will be molded in the drag because the possible defects due to loose sand and inclusions will occur in the cope.

6. As far as possible, full cores should be used instead of cemented half cores for reducing cost and for accuracy.

7. For mass production, the use of several patterns in a mould with common riser is to be preferred.

8. The pattern should have very good surface finish as it directly affects the corresponding finish of the casting.

9. Shape and size of the casting and that of the core should be carefully considered to decide the size and location of the core prints.

10. Proper material should always be selected for the pattern after carefully analyzing the factors responsible for their selection.

11. Try to employ full cores always instead of jointed half cores as far as possible. This will reduce cost and ensure greater dimensional accuracy.

12. The use of offset parting, instead of cores as for as possible should be encouraged to the great extent.

13. For large scale production of small castings, the use of gated or match- plate patterns should be preferred wherever the existing facilities permit.

14. If gates, runners and risers are required to be attached with the pattern, they should be properly located and their sudden variation in dimensions should be avoided.

15. Wherever there is a sharp corner, a fillet should be provided, and the corners may be rounded up for easy withdrawal of patterns as well as easy flow of molten metal in the mould.

16. Proper allowances should be provided, wherever necessary.

17. As for as possible, the pattern should have a good surface finish because the surface finish of the casting depends totally on the surface finish of the pattern and the kind of facing of the mold cavity. Copied from Introduction to Basic Manufacturing Processes and Workshop Technology by Rajender Singh.