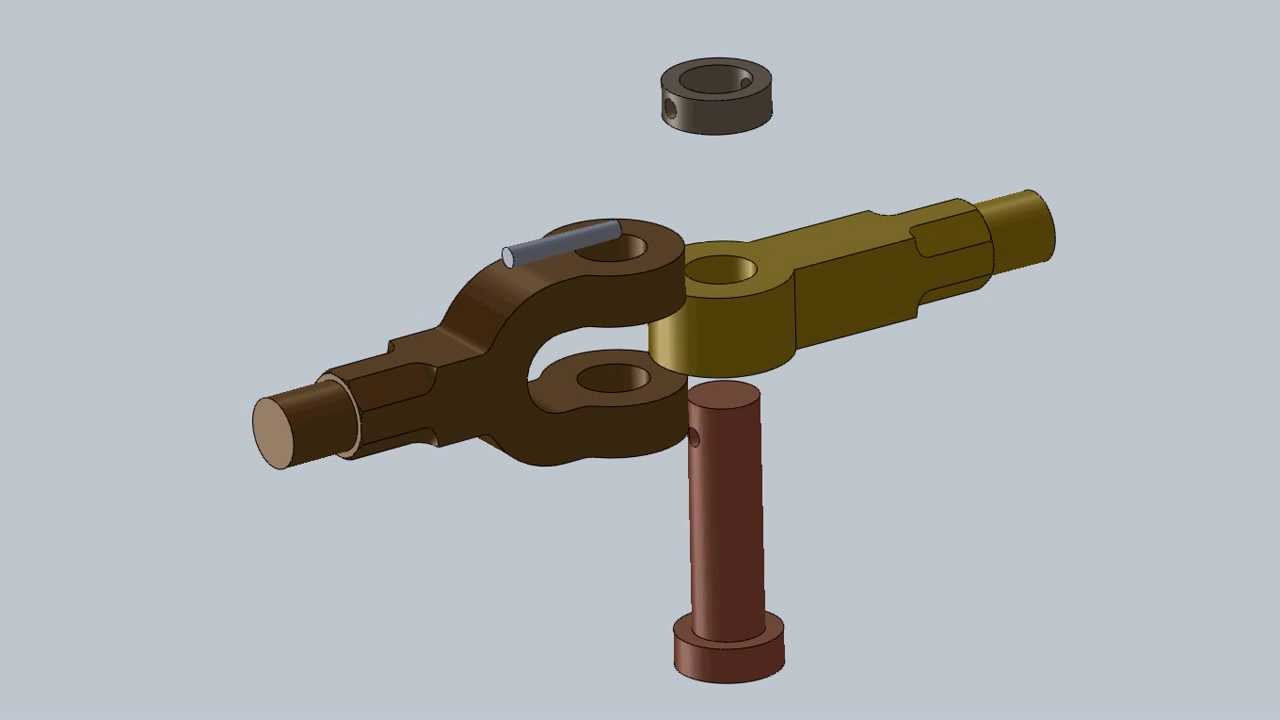

Design of Knuckle Joint :

A knuckle joint is a mechanical joint used to connect two rods which are under a tensile load, when there is a requirement of small amount of flexibility, or angular moment is necessary.

The empirical dimensions as discussed in Art. 12.13 have been formulated after wide experience on a particular service. These dimensions are of more practical value than the theoretical analysis. Thus, a designer should consider the empirical relations in designing a knuckle joint. The following procedure for Design of Knuckle Joint may be adopted :

1. First of all, find the diameter of the rod by considering the failure of the rod in tension. We know that tensile load acting on the rod,

P = [π × (d)^2× σt] / 4

where d = Diameter of the rod, and

σt = Permissible tensile stress for the material of the rod.

2. After determining the diameter of the rod, the diameter of pin (d1) may be determined by considering the failure of the pin in shear. We know that load,

P = 2 × {[π × (d)^2× τ] / 4}

A little consideration will show that the value of d1 as obtained by the above relation is less than the specified value (i.e. the diameter of rod). So fix the diameter of the pin equal to the diameter of the rod.

3. Other dimensions of the joint are fixed by empirical relations as discussed in Art. 12.13.

4. The induced stresses are obtained by substituting the empirical dimensions in the relations as discussed in Art. 12.14.

In case the induced stress is more than the allowable stress, then the corresponding dimension may be increased.

A knuckle joint is a mechanical joint used to connect two rods which are under a tensile load, when there is a requirement of small amount of flexibility, or angular moment is necessary. There is always axial or linear line of action of load.

knuckle joint

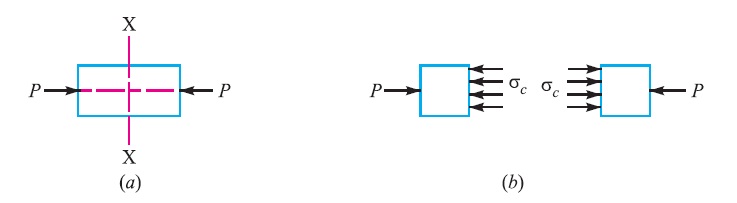

Methods of Failure of Knuckle Joint

Reference A Textbook of a Machine Design by R.S. Khurmi and J.K. Gupta