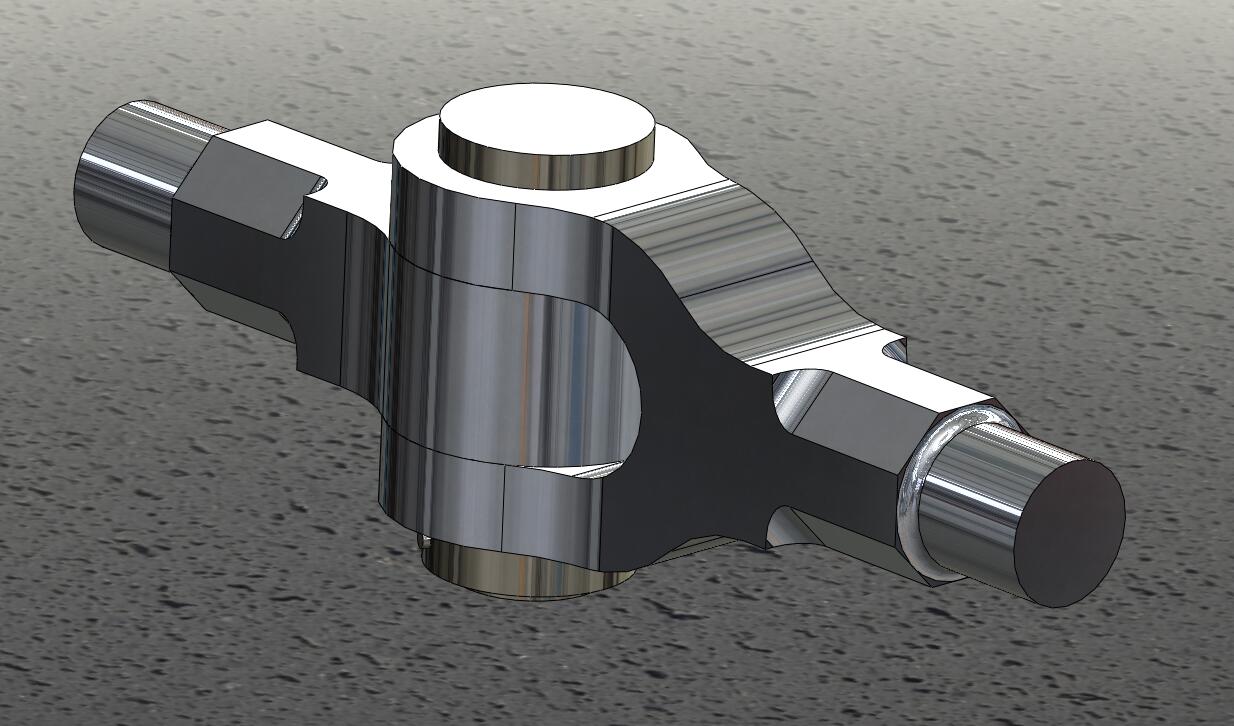

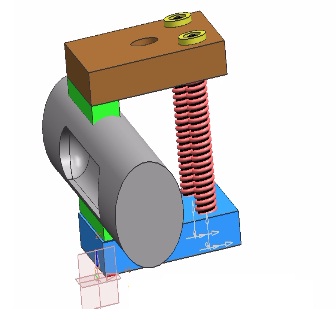

FABRICATION OF KEYWAY(SLOTTING FIXTURE) ATTACHMENT FOR LATHE

Abstract

Mechanical engineering without production and manufacturing is meaningless and inseparable. Production and manufacturing process deals with conversion of raw materials inputs to finished products as per required dimensions specifications and efficiently using recent technology

In order to perform different operation in a lathe such as different type of turning, chamfering, polishing, grooving, thread cutting, filling, knurling etc. In this project we have to decide that the keyway operation can be done using conventional lathe with help of keyway attachment. Our project is based on the need for the work holding devices.

This fabrication which will enable the operation keyway process easier. In generally the slotting/milling operation can be performed by slotting machine but in this case the keyway operation can be done using conventional lathe through keyway attachment

Our project have the following objectives

1. To reduce the lead time.

2. To increase the productivity by using keyway attachment which is attached in the lathe?

3. Even an unskilled technician can use them

4. No need for purchasing special machine for keyway ie. Slotting/milling

With these features, we sincerely hope that our project serve as a valuable project. We welcome the correction, comments based on our project.

Advantage

1) Fixture cost is low

2) No need of purchase special machine for this

3) Production cost is low

Disadvantage

1) Accuracy is little bit low