GENERAL CONSIDERATIONS ADOPTED FOR DESIGNING A FORGING JOB

There are some common considerations adopted while designing a forging job and the same are given below.

1. Sufficient draft on surfaces should be provided to facilitate easy removal of forgings from the dies. It depends mainly on the depth of the die cavity. The greater the depth, the larger draft will be the required. Generally, however, a 1 to 5 degrees draft is provided on press forgings and 3 to 10 degrees on drop forgings.

2. Sharp corners where ever occur should always be avoided as far as possible to prevent concentration of stresses leading to fatigue failures and to facilitate ease in forging. The usual practice is to provide fillets of more than 1.6 mm radius. The exact size of the fillet is however decided according the size of the forging. If a perfectly sharp corner is required, the fillet can be removed at later stage.

3. Forgings which are likely to carry flash, such as in drop and press forgings, should preferably have the parting line in such a position that the same will divide them in two equal halves.

4. As far as possible the parting line of a forging should lie in one plane.

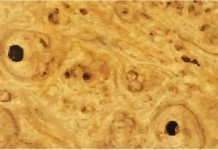

5. The forged component should ultimately be able to achieve a radial flow of grains or fibres.

6. Attention should be given to avoid the presence of pockets and recesses in forgings.

If they cannot be avoided, their number should be reduced to a minimum as far as possible.

7. High and thin ribs should not be designed. Also, cavities which are deeper than their diameters should be avoided.

8. Metal shrinkage and forging method should be duly taken into account while deciding the forging and finishing temperatures.

9. Although it is possible to achieve quite close tolerances of the order of 0.4 mm on either side through forging and therefore it is adequate to provide allowances to compensate for metal shrinkage, machining, die wear, trimming and mis-match of dies.

10. Too thin sections in parts should be avoided to facilitate an easy flow of metal. Source Introduction of a Basic Manufacturing Processes and Workshop Technology by Rajender Singh.