Hot Piercing or Seamless tubing

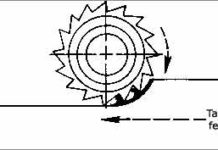

Hot piercing is also known as seamless tubing or roll piercing process. The process setup is shown in Fig. It is used for making thinwalled round objects. Seamless tube forming is

popular and economical process in comparison to machining because it saves material wasted in boring of parts.

Hot pircing includes rotary piercing to obtain formed tube by piercing a pointed mandrel through a billet in a specially designed rolling mill. The rotary piercing can be performed either on a two-high rolling mill or on a three-high rolling mill. In the former, the two rolls are set at an angle to each other. The billet under the rolls is deformed and a cavity formation is initiated at the centre due to tensile stressing. The carefully profiled shape of the mandrel assists and controls the formation of cavity. In a three-high rolling mill, the three shaped rolls are located at 1200 and their axes are inclined at a feed angle to permit forward and rotary motion of the billet. The squeezing and bulging of the billet open up a seam in its center pass makes a rather thick-walled tube which is again passed over plug and through grooved rolls in a two-high roll mill where the thickness is decreased and the length is increased. While it is still up to a temperature, it is passed on to a reeling machine which has two rolls similar to the piercing rolls, but with flat surfaces. If more accuracy and better finish are desired, the run through sizing dies or rolls. After cooling, the tubes are used in a pickling bath of dilute sulphuric acid to remove the scale. Source Introduction of a Basic Manufacturing Processes and Workshop Technology by Rajender Singh.