Inspection Gauges

Inspection gauges are commonly employed to avoid costly and lengthy process of testing the component dimensions. Fig. represented the principle of limit gauging. These gauges are basically used for checking the size, shape and relative positions of various parts. These are of fixed type measuring devices and are classified as standard and limit. Standard gauges are made to the nominal size of the part to be tested and have the measuring member equal in size to the mean permissible dimension of the part to be checked. Limit gauges or “go” and “no go” gauges are made to the limit sizes of the job to be measured. Sides or ends of the gauge are made corresponding to maximum and minimum permissible size of the job for its acceptance or rejection. The objective of limit gauges is to identify whether the actual dimensions of the work are within or outside the specified limits of acceptance. The double end kind of limit gauge has the GO portion at one end and the NO GO portion at the other end. GO portion must pass into or over an acceptable piece but the NO GO portion should not pass. Inspection gauges may be classified as working, inspection, and reference or master gauges. The working and inspection gauges are generally employed for inspection of components

from stage to stage.

Reference or master gauges are needed only for checking the size or condition of other gauges. The gauges are generally classified into:

1. Gauges for checking shafts

2. Gauges for checking holes

3. Gauges for checking forms

4. Gauges for checking threads

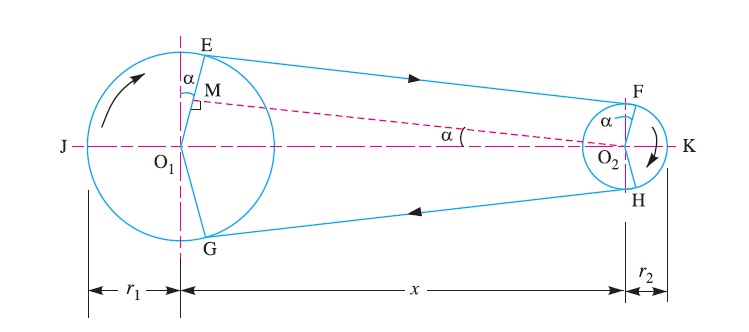

5. Gauges for checking tapers

The gauges commonly used in production work are

1. Progressive or step plug gauge

2. Thread plug gauge

3. A combination of internal and external non adjustable gauges

4. Ring gauge

5. Snap gauges

6. Feeler gauge

7. Wire gauge

8. Template gauge

9. Adjustable gap gauge

10. Screw pitch gauge

11. Fillet and radius gauge

For manufacturing the above gauges, high carbon and alloy steels materials are commonly employed for manufacturing or production of gauges. Steel gauges may be used subject to some distortion during hardening. These difficulties can be overcome by making gauges by use of cemented carbide material or providing chrome plating at the surface of the gauge. Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.