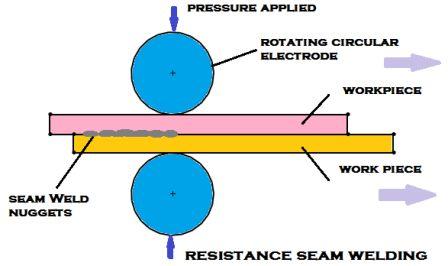

Resistance Seam Welding

It is a continuous type of spot welding wherein spot welds overlap each other to the desired extent. In this process coalescence at the faying surfaces is produced by the heat obtained from the resistance to electric current (flow) through the work pieces held together under pressure by circular electrodes. The resulting weld is a series of overlapping resistance-spots welds made progressively along a joint by rotating the circular electrodes. The principle of seam welding is shown in Fig. and resistance seam welding process set up is shown in Fig. The seam welding is similar to spot welding, except that circular rolling electrodes are used to produce a continuous air-tight seam of overlapping welds. Overlapping continuous spot welds seams are produced by the rotating electrodes and a regularly interrupted current.

Applications

1. It is used for making leak proof joints in fuel tanks of automobiles.

2. Except for copper and high copper alloys, most other metals can be seam welded.

3. It is also used for making flange welds for use in watertight tanks.

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.