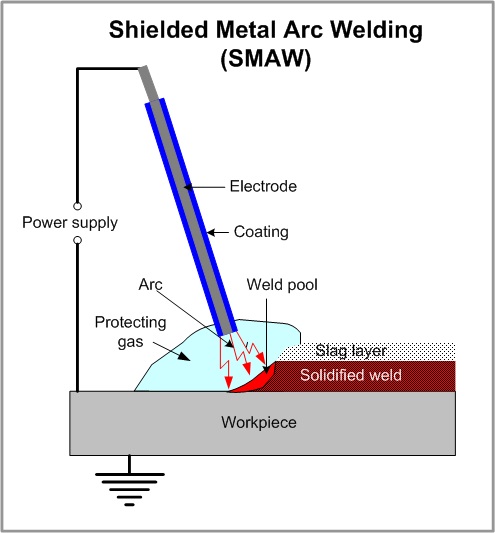

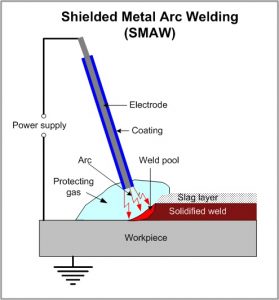

Shielded Metal Arc Welding (SMAW)

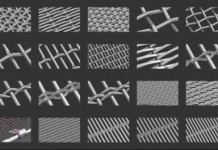

Shielded metal arc welding (SMAW) is a commonly used arc welding process manually carried by welder. It is an arc welding process in which heat for welding is produced through an electric arc set up between a flux coated electrode and the workpiece. The flux coating of electrode decomposes due to arc heat and serves many functions, like weld metal protection, arc stability etc. Inner core of the electrode supply the filler material for making a weld. The basic setup of MMAW is depicted in Fig. and the configuration of weld zone is shown in Fig. If the parent metal is thick it may be necessary to make two or three passes for completing the weld. A typical multi pass bead in this case is shown in Fig.

Advantages

1. Shielded Metal Arc Welding (SMAW) can be carried out in any position with highest weld quality.

2. MMAW is the simplest of all the arc welding processes.

3. This welding process finds innumerable applications, because of the availability of a wide variety of electrodes.

4. Big range of metals and their alloys can be welded easily.

5. The process can be very well employed for hard facing and metal resistance etc.

6. Joints (e.g., between nozzles and shell in a pressure vessel) which because of their position are difficult to be welded by automatic welding machines can be easily accomplished by flux shielded metal arc welding.

7. The MMAW welding equipment is portable and the cost is fairly low.

Limitations

1. Due to flux coated electrodes, the chances of slag entrapment and other related defects are more as compared to MIG and TIG welding.

2. Duo to fumes and particles of slag, the arc and metal transfer is not very clear and thus welding control in this process is a bit difficult as compared to MIG welding.

3. Due to limited length of each electrode and brittle flux coating on it, mechanization is difficult.

4. In welding long joints (e.g., in pressure vessels), as one electrode finishes, the weld is to be progressed with the next electrode. Unless properly cared, a defect (like slag inclusion or insufficient penetration) may occur at the place where welding is restarted with the new electrode

5. The process uses stick electrodes and thus it is slower as compared to MIG welding.

Applications

1. Today, almost all the commonly employed metals and their alloys can be welded by this process.

2. Shielded metal arc welding is used both as a fabrication process and for maintenance and repair jobs.

3. The process finds applications in

(a) Building and Bridge construction

(b) Automotive and aircraft industry, etc.

(c) Air receiver, tank, boiler and pressure vessel fabrication

(d) Ship building

(e) Pipes and

(f) Penstock joining

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Songh.