THERMIT WELDING

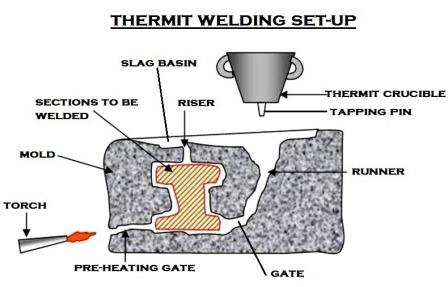

It may be of forge or fusion kind of welding. Fusion welding requires no pressure. Thermit welding process is depicted in Fig. It is a process which uses a mixture of iron oxide and granular aluminium. This mixture in superheat liquid state is poured around the parts to be joined. The joint is equipped with the refractory mold structure all around. In case of thermit pressure welding, only the heat of thermit reaction is utilized to bring the surface of metal to be welded in plastic state and pressure is the applied to complete the weld. The temperature produced in the thermit reaction is of the order of 3000°C. Thermit welding is used for welding pipes, cables, conductors, shafts, and broken machinery frames, rails and repair of large gear tooth.

Thermit Welding Powder, also known as Thermit bonding and Thermit welding is a welding process for joining two electrical conductors that employs superheated copper alloy to permanently join the conductors. The process employs an Thermit reaction of a copper Thermit composition to heat the copper, and requires no external source of heat or current. The chemical reaction that produces the heat is an aluminothermic reaction between aluminum powder and a metal oxide. The reaction reaches very high temperatures, depending on The metal oxide used. The reactants are usually supplied In the form of powders, with the reaction triggered using a Spark from a flint lighter. The activation energy for this reaction Is very high however, and initiation requires either the use of A “booster” material such as powdered magnesium metal or a Very hot flame source. The aluminum oxide slag that it produces Is discarded. When welding copper conductors, the process employs a Semi-permanent graphite crucible mould, in which the molten Copper, produced by the reaction, flows through the mould and over and around the conductors to be welded, forming an Electrically conductive weld between them. When the copper cools, the mould is either broken off or left in place. Alternatively, hand-held graphite crucibles can be used. The advantages of these crucibles include portability, lower cost (because they can be reused), and flexibility, especially in field applications. The weld formed has higher mechanical strength than other forms of weld, and excellent corrosion resistance. It is also highly stable when subject to repeated short-circuit pulses, and does not suffer from increased electrical resistance over the lifetime of the installation. However, the process is costly relative to other welding processes, requires a supply of replaceable moulds, suffers from a lack of repeatability, and can be impeded by wet conditions or bad weather (when performed outdoors).

Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.