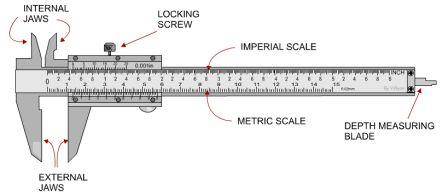

Vernier Caliper

Fig. shows the vernier caliper, which is commonly used to measure accurately

(1) outside diameters of shafts,

(2) thicknesses of various parts,

(3) diameters of holes or rings and

(4) internal dimensions of hollow jobs or articles.

It works on the principle of vernier and can measure the dimensions to an accuracy of 0.02 mm. For making a measurement of external dimensions, the job is placed between thefixed and the movable jaws. The movable or the sliding jaw is moved until it almost contacts the job kept against the fixed jaw. The sliding jaw assembly of the vernier caliper that carries the fine adjustment screw should be clamped to the graduated beam with the help of adjustment clamp. The two jaws are then brought into contact with the job by moving the sliding jaw with the help of fine adjustment screw. The jaws should make now definite contact with the job but should not be tight. The main slide assembly is then locked to the beam with help of clamp. The caliper is then carefully removed from the job to prevent springing the jaws and the reading is taken. For making a measurement of internal dimensions, the job is placed outward between the fixed and the movable jaws meant for measuring inner dimension. Source A Textbook of Basic Manufacturing Processes and Workshop Technology by Rajender Singh.